strength, stability, performance, safety, and comfort. In an effort to

evaluate the company's claims, I began with a close look at what was going

on in the mold room. What I saw was a flashback to the way good sailboats

once were built. Serrated rollers, carefully catalyzed bucket-mixed resin,

and lots of attention to detail are at the heart of the process. Valiant's

recipe for solid-FRP hull building would be called primitive by race-boat

builders, but for serious ocean passagemakers who are most interested in

long-term structural integrity, the rugged keep-it-simple philosophy makes

lots of sense.

How does Valiant get away with such

low-tech building methods? The answer is simple: good craftsmanship. The

hulls develop stiffness through extra laminate thickness and the bonding of

all interior parts to the hull. In the case of a grounding or a collision

with flotsam, this thicker hull skin means improved tough-

|

ness and point-load resistance. The extra weight associated with the extra

material is near the boat's center of gravity; hence, it doesn't detract

much from the performance of this moderate-displacement cutter. Similarly

built boats from three decades ago are still going strong, and longevity is

certainly a valuable by-product of strength.

You can see

Valiant's back-to-basics hull-building approach in the materials it uses.

There's only one type of isophthalic polyester resin in the shop, and the

laminate schedule is composed of different numbers of layers of 1 1/2-ounce

mat and 24-ounce woven roving, the proven workhorses of FRP fabrics. There's

five to six layers of reinforcement at the sheer, 11 layers at the waterline,

and 20 at the base of the keel stub.

The crew knows that

how you laminate is just as important as how much and what type of material

you use. The guys applying

|

|

layer after layer

demonstrate an attention to detail that's a cut above what we've come to see as

standard industry practice. The Valiant 50 hull is certainly Texas tough.

A Stable Platform

|

holder. The Valiant 50 is no lightweight race boat masquerading as a cruiser,

but neither is it a houseboat unable to tick off serious passage miles. In

truth, I was surprised to see how well the modest-

|

|

|

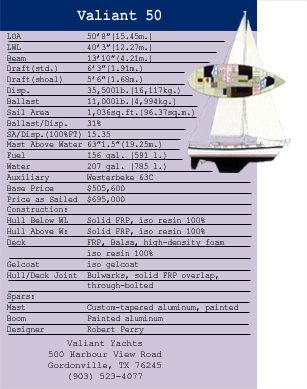

With substantial waterline and beam, the Valiant 50 has

good form stability. It's stiff. It's modest 31-percent ballast ratio and

6-foot-3-inch draft afford adequate righting moment and a positive righting

angle to 125 degrees.

However, compared with the Valiant

42's 134-degree range of positive stability, the V-50 does reflect its lower

ballast/displacement ratio. Granted, larger vessels resist capsize more

effectively than smaller vessels, so some decrease in the range of positive

stability can be tolerated. The V-50's long keel foot keeps the CG of lead

ballast reasonably low, and the solidly built cabin house would contribute

to getting the vessel right side up if a wave-induced capsize ever occurred.

Will She Sail?

Performance is like beauty:

It shifts with the eye of the be-

|

sized double-spreader-rigged cutter could move the boat in winds under 10 knots.

It's

a close-winded cruiser with enough uphill manners to make the inevitable beat

doable. Best of all, it has a sail plan that two people can handle, assuming

the crew is fit and willing.

What makes this boat's

sailing manners so appealing is the refinement that has gone on over the years.

Feedback from round-the-world racer Mark Schrader and others who have spent

sea time aboard Valiants have helped fine-tune the placement of sheet leads,

travelers, and winches. The big Lewmar 66 primaries, like the mainsheet-traveler

controls and the stay-

|

|

|